Berny Marsden’s Stitch and Glue W Kayak – United Kingdom

This is the latest DIY W kayak project –

It’s the first DIY design allowing to take the boat apart.

Read Berny’s account on the comments section: http://micronautical.com/diy-kayak-design/#comment-90

NEW: View Berny’s first test movie of his motorized W kayk ‘Banana Split’ –

John Forney’s Wooden W Kayak – Texas

John is an prolific small-boat designer and builder from Texas, who’s built fifteen boats in recent years, including designs in wood, composites and skin-on-frame.

John says: -“My interest in boat building had waned somewhat, primarily because I couldn’t crack the nut of fishing comfortably from a small paddle craft. The W concept has completely reinvigorated my interest in boat building.”

John first W boat is 12 feet long and 30 inches wide, and it weighs 74 lbs. It can take two large size fishermen with all their fishing and camping gear.

-“Standing up in this boat is as natural as breathing. One just doesn’t get the sense that anything will go wrong.” he says.

John’s next project is a ten footer skin-on-frame W kayak.

Email John Forney

- John standing in the wooden twin hull fishing kayak he created

“I’m on the Brazos River with my wife this day. I painted the boat Navy Blue Marine Polyurethane paint on the outside, with white Marine paint on the inside.”

- Wooden twin hull fishing kayak / unfinished

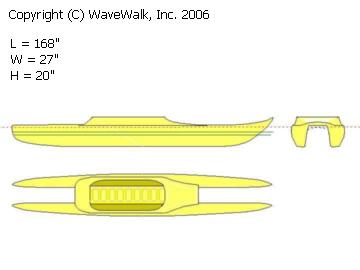

16 ft Long Fiberglass W Kayak

This is a 16 ft long W kayak project realized in Europe:

- 16 ft long W kayak project – Europe

The design of this fine looking W kayak was based on a concept published on this website back in 2006:

More technical info on speed, stability, propulsion ergonomics and other design issues related to fishing kayaks >