How are these small boats made?

Here is a glimpse into the process of making a mold for Wavewalk’s newest portable skiff, the Series 4 –

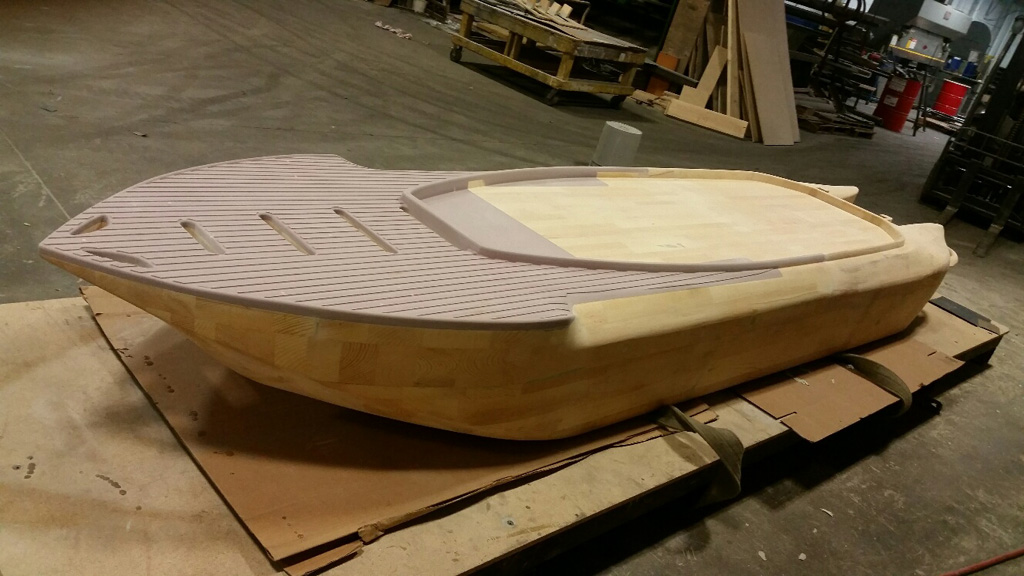

The pictures below show the wooden pattern produced from solid wood and hard rubber from the CAD (computer Aided design) file for the product. This first-generation mold will be used to produce a second generation mold called a sand mold. The mold makers will cast molten aluminum into the sand mold, and produce the actual rotational mold in which molders will pour Polyethylene resin, and produce the Series 4 boats.